DFM® Tools

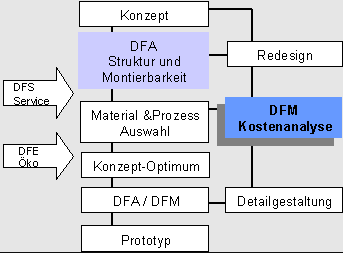

Whenever information about part costs, process costs or tooling costs is required, the DFM service is used.

Deployment

The DFM service is used whenever information about part costs, process costs or tooling costs is required. This may be for purposes such as improving designs, finding the most economical manufacturing process or negotiating with suppliers.

Essentially, DFM is used in the second step of DFMA for the preventive optimisation of product costs, for the selection of materials and economical processes.

Procedure

As with the DFA service, the approach consists of finding new, better solutions and cost values by answering interactive questions posed by experts. This allows new ideas to be sought and analysed according to cost criteria. The cost values determined in parallel by the tool (material, process, tool) help to further optimise the solutions in a cost-oriented manner in the next step of detailing, often following a DFA session.

This approach supports the team in the gradual optimisation process, from the preliminary study and conception to the prototype and actual implementation.

The DFM-Tool

The DFM tool from amc is a technical analysis software for analysing and optimising the costs of parts (material, process and tooling costs) during the manufacturing process. The software determines the most important cost drivers in connection with a range of processes for parts manufacturing and surface treatment.

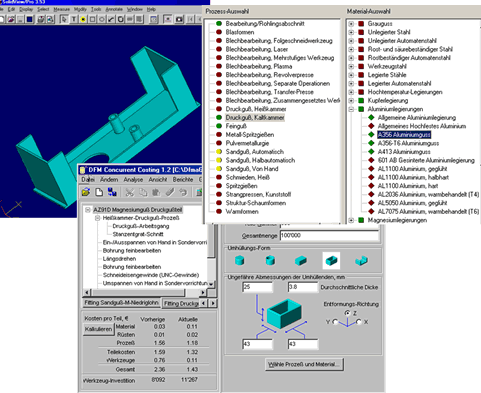

The DFM costing tool

The DFM costing tool allows users to import data from 3D CAD systems. Data can be imported from common CAD systems such as Pro/Engineer, Catia, Unigraphics, Parasolids and I-DEAS (SDRC MCA) or via the STL and IGES-VDA file formats.

This also enables highly efficient calculations to accompany the design process. When a CAD file is opened, the part size, weight, volume, number of surfaces and other measurement units are automatically transferred to DFM. Once the product engineer has selected different materials and the manufacturing process for the part, the DFM tool uses the imported geometry of the 3D part to determine the material, process and tooling costs.

DFM delivers

Many different manufacturing processes and a comprehensive material database for the development team to support material and process selection during the early development stage of the design. For example:

- Mechanically processed parts (such as turning, drilling, grinding, broaching) and their processes

- Sheet metal parts, their processes and tooling costs

- Plastic parts, their processes and tooling costs

- Die-cast parts, their processes and tooling costs (cold and hot chamber processes)

- Parts manufactured using the lost wax process (lost mould or investment casting)

- Parts manufactured manually, semi-automatically or automatically using sand casting, including the processes and tools involved

- Sintered parts, their processes and tooling costs

- Forged parts and their tooling costs

A second, expanded operations library also contains information about special processes such as:

packaging, surface treatment, heat treatment, testing, etc.

The third data source contains all the necessary values for processing the materials in the various processes. Cost statements about designs and selected solutions during the design phase encourage engineers to choose the most cost-effective manufacturing process for the part and to consider how part features need to be modified individually in order to optimise manufacturing costs.

Typical DFM applications

Here is a summary of some important applications from a range of possible uses:

• Optimise the design of individual parts (material)

• Optimisation of parts in terms of tools or process times

• Finding the appropriate manufacturing process and manufacturer

• Documentation of costs and manufacturing data

• Competitor analyses / concept comparisons

• Cost disclosure and negotiations with subcontractors

Get started now!

In the DFMA forum, you will learn about the DFMA methodology using a case study and numerous application examples.