Tools

A range of tools support the preventive optimization process and its various applications in industrial practice.

DFMA® Methods Tools

![dfa10full[1]](https://dfma.de/wp-content/uploads/2023/02/dfa10full1.jpg)

DFA®

This is the part for product simplification, which systematizes the preventive reduction of product costs during the development process in order to achieve a competitive market price more quickly, as well as supporting teamwork. As a basic part of the DFMA process, it is used in over 80% of applications.

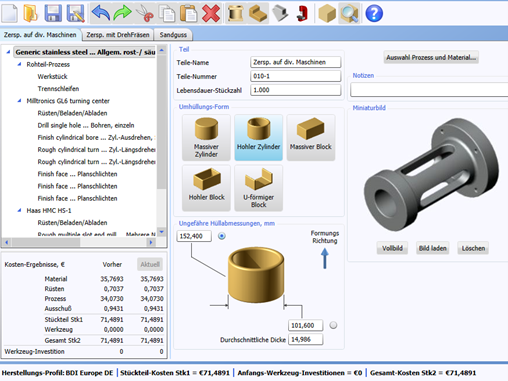

DFM®

Helps to determine the manufacturing process and part costs preventively, investigate alternative processes, find the most economical one, and thus optimize part costs and tooling costs at an early stage. It is primarily used to accelerate the determination of cost information and, in particular, cost disclosure. In particular, engineers provide support in the more systematic identification of cost drivers and find alternatives to optimize solutions.

DFS

This is the tool for optimizing service tasks that are prone to failure. DFS improves customer satisfaction and also extends the service life of the product, thereby improving environmental compatibility.

DFE

This is a tool for planning and optimizing the economic and ecological consequences at the end of the product cycle. It supports the reduction of environmental impact and promotes the reusability of products, also from an economic point of view for the manufacturing company.

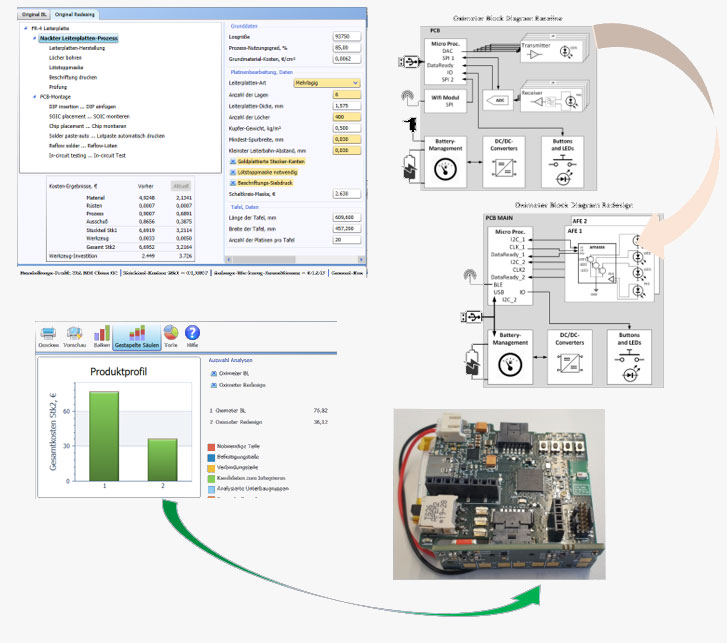

DFMA special solution for electronics and PCBs

The flexibility of the DFMA method is also evident in its adaptability to specific processes, such as the optimization of electronics for the subsequent manufacture of printed circuit boards (PCBs). The path leads from the baseline to the methodological optimization of the functional blocks to the redesign and then to the finished product.

Get started now!

In the DFMA forum, you will learn about the DFMA methodology using a case study and numerous application examples.